Injecting a "smart" soul into the packaging industry

Guangdong Zhixing Machinery Co., Ltd. has outstanding achievements in the fields of intelligent packaging, sorting and processing, and intellectual property.

Intelligent production line that integrates unpacking, packing and sealing

The launch of China Packaging Industry Development Plan (2016-2020) will include “smart packaging” and “green packaging, safe packaging” in the overall goal of the packaging industry.With the development of production and manufacturing, the individualization, customization and intelligence of the packaging industry will also bring new breakthroughs to the development of the industry.The intelligent packing operation unit integrates automatic unpacking, automatic packing and automatic folding and sealing into one, which brings higher value to customers.

In this unit, the worker only needs to place the unopened stack of cartons in the storage mechanism of the unpacker. After the automatic unpacking is completed, the boxing robot will automatically grab (suck) the finished product to the box to be packed. In the empty carton, after the boxing operation is completed, the power roller will transport the full box to the automatic folding and sealing machine to complete the operation of folding and sealing tape. Whether it's labor cost or productivity, the solution has achieved an unprecedented renewed iteration.

Accuracy is at a new high, and the robot can be used to “carry the parts inside the container”.

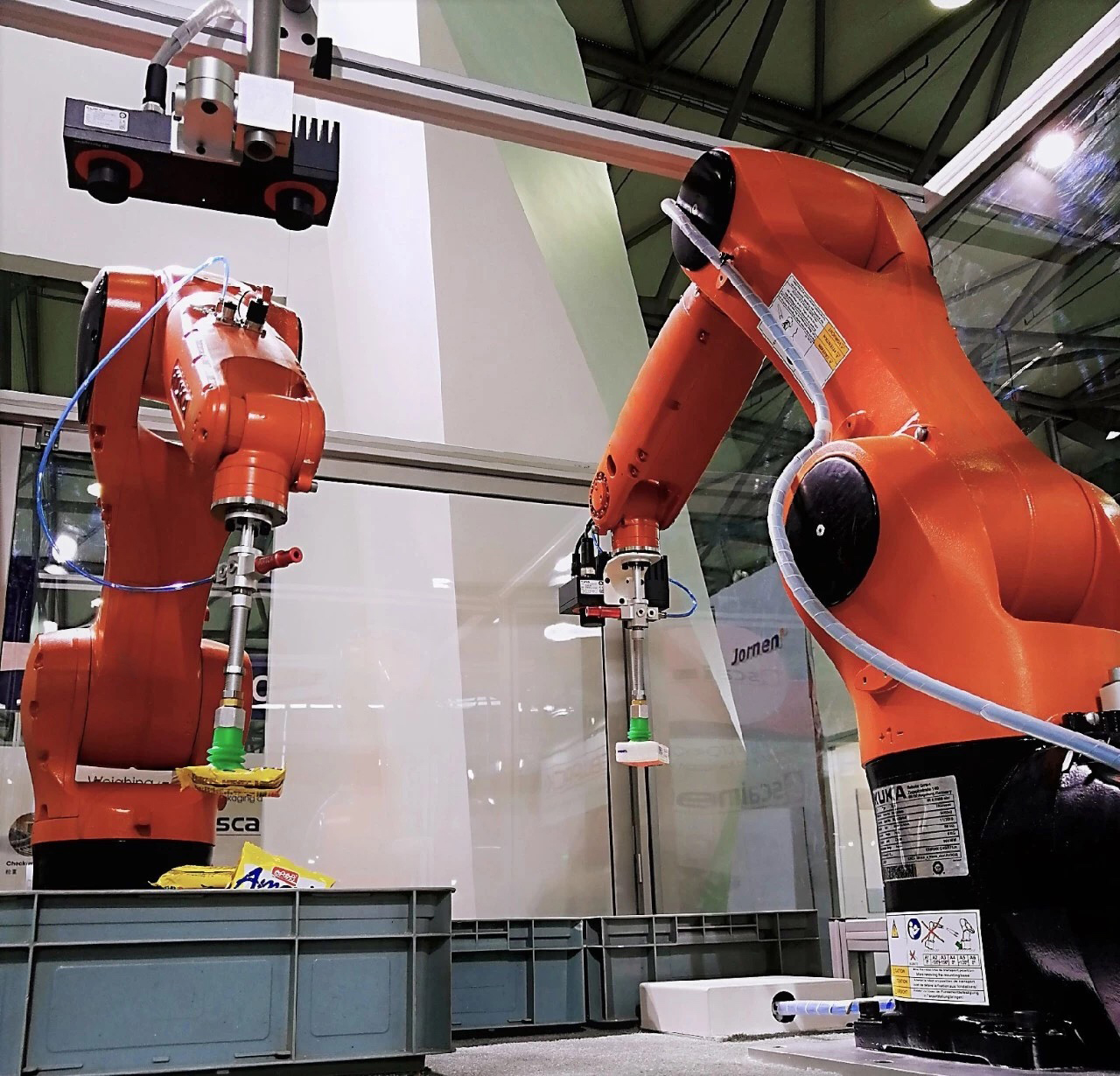

With the full deployment of smart manufacturing in the global automation market, machine vision technology has begun to be valued in various fields, especially for “object grabbing” operations. With the diversification and refinement of the manufacturing industry, the position, orientation, type, shape and size of the objects are more and more diverse, and higher requirements are placed on the accuracy and precision of the robot.

The automatic grab robot application automatically leads the industry in terms of precision, and it achieves “carrying parts in the container”. The application integrates 3D sensors, robots and related software to automatically identify the appropriate gripping surface for the workpiece in six dimensions. It also identifies the container in which the workpiece is located and provides information to the robot to ensure that it does not collide with the container during the grab operation. The entire process requires no manual intervention to meet the urgent needs of the logistics and consumer goods sectors.